ZMGF2200 Flute Lamination Machine Automatic With CE Shied For printing

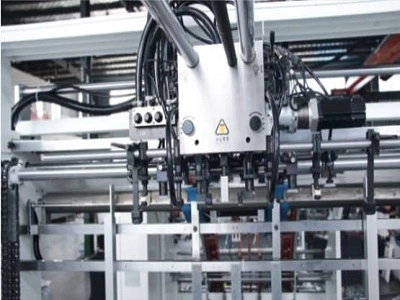

Structure:

A. Top sheet Feeder: It can send stacks of 120-800gsm paper from above.

B. Bottom sheet feeder: It can send 0.5~10mm Corrugated/paperboard from below.

C. Gluing mechanism: The glued water can be applied to the fed paper. Glue roller is stainless steel.

D. Calibration structure-Fits the two papers according to the set tolerances.

E. Pressing Conveyor: Presses the attached paper and conveys it to the delivery section.

The frames of this series of products are all processed at one time by a large-scale machining center, which ensures the accuracy of each station and ensures more stable operation of the equipment

Parameters

| Model |

ZGFM1500 |

ZGFM1700 |

ZGFM1900 |

ZGFM1900 |

| Max size |

1500*1500mm |

1700*1700mm |

1900*1900mm |

2200*2200mm |

| Min size |

360*380mm |

360*400mm |

500*500mm |

500*500mm |

| Top Paper |

150-800g |

150-800g |

150-800g |

150-800g |

| Bottom paper |

≤10mmABCDEF corrugated board

≥300gsm cardboard

|

≤10mm ABCDEF corrugated board

≥300gsm cardboard

|

≤10mmABCDEFcorrugated board

≥300gsm cardboard

|

≤10mmABCDEFcorrugated board

≥300gsm cardboard

|

|

Max laminating

speed

|

160m/min |

160m/min |

160m/min |

160m/min |

| Power |

20kw |

20kw |

22KW |

22KW |

| Stick accuracy |

±1mm |

±1mm |

±1mm |

±1mm |

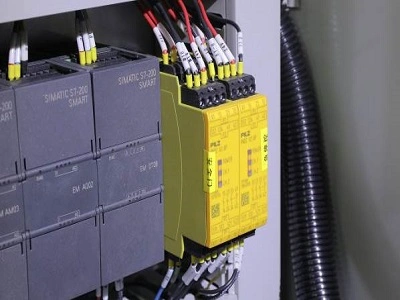

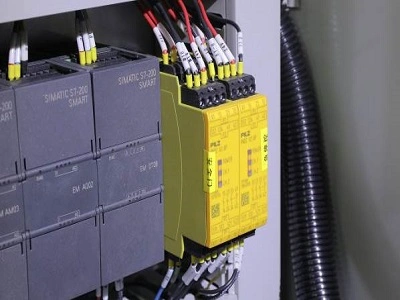

EXTRA SAFETY GUARD AND SAFETY RELAY:

Performance characteristics:

A .Cardboard laminate with corrugated or cardboard laminate with cardboard.

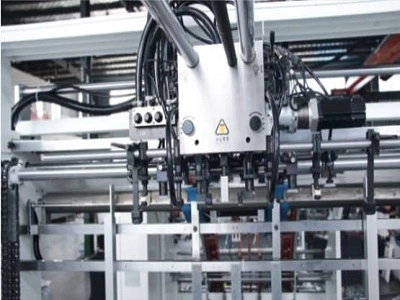

B. Automatic detection of top and bottom paper, automatic servo correction technology. Make the top paper automatically track and fit the bottom paper, and the accuracy is high.

C. The bottom paper feeding part use imported servo motor controlling system, with Japan NITTA suction belt and big air blower to ensure smooth feeding of 2ply, 3ply, 4ply, 5ply and cardboard.

D. The multifunctional rack of the bottom paper are suitable for curved corrugated.

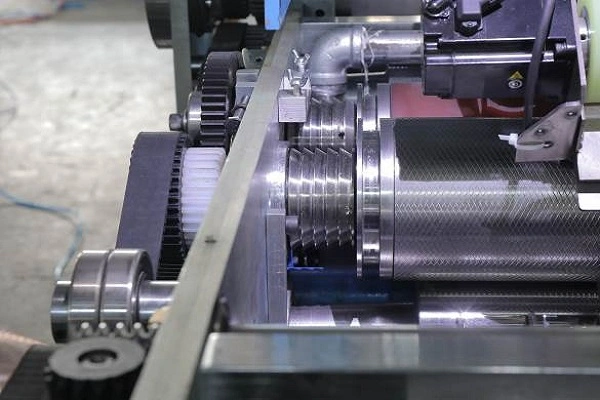

E. Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min glue quantity.

F. Use a circulating glue system to reduce glue loss and stabilize glue adhesion effect.

G. One -click adjustment of the whole machine (just enter the paper size).

H. Automatic paper collection and manual paper collection can be converted at any time.

I. Video monitoring (optional).

FEATURES

1.BOTTOM SHEET FEEDING

Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller; Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation.

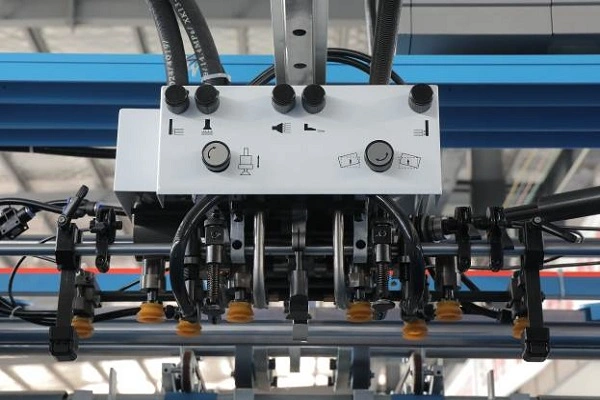

2.TOP SHEET FEEDING MECHANISM

Both paper lifting and feeding nozzle of high speed auto dedicated feeder can be freely adjusted to be adapted to both thin and thick paper. Together with Becker pump, ensure top feeding paper run fast and smoothly.

3.ELECTRICAL SYSTEM

Designed and adopt U.S.A Parker motion controller together with Yaskawa Servo system and inverter, Siemens PLC to ensure machine run at max. speed and accuracy as premium performance and running stability.

4.PRE-STACK PART

Pre-pile system with preset function can be set as paper size through touch screen and oriented automatically to reduce set-up time efficiently.

5.Transmission System

Gates synchronical belt together with SKF bearing as main transmission is adopted to ensure stability. Both pressure rollers, dampening roller and glue value can be easily adjusted by handle with mechanical encoder.

6. POSITIONING SYSTEM & GLUE ROLLER

Photocell together with Parker Dynamic module and Yaskawa Servo system ensure the accuracy of orientation of top and bottom paper. Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min. glue quantity.

7. TOUCH SCREEN OPERATION SYSTEM

It adopts the centralized control of the touch screen, realizes the man-machine dialogue with the high-resolution man-machine interface, and realizes the real-time dynamic monitoring of operation and fault, making it more convenient to adjust and troubleshoot.

OPTIONS:

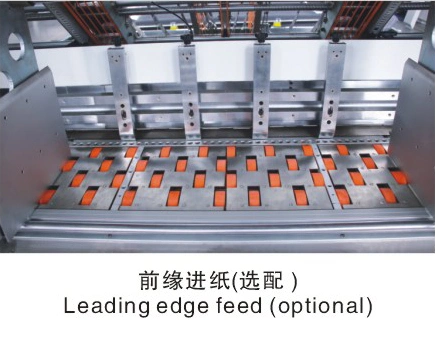

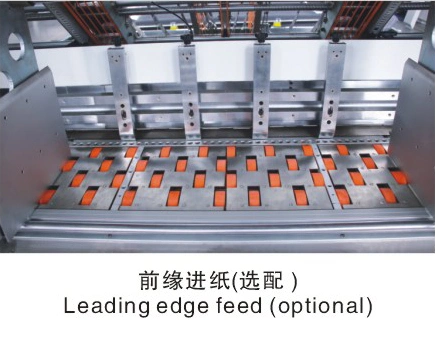

1.LEADING EDGE FEEDING SYSTEM

Lead edge ensure thick corrugated board like 5 or 7 layers run smoothly even under very curing condition.

2.SHAFTLESS SERVO FEEDER

Shaftless servo feeder is utilized for extra long sheet at flexible motion.

3. AUTOMATIC LUBRICATION SYSTEM

Automatic lubrication pump for all main bearing ensure machine strong endurance even under heavy duty working condition.

Machine transport and packing

Company profile:

We are a professional company which manufactures and sells printing machines and office equipment. Our high quality products and perfect service have enjoyed a high reputation in the industry. Moreover, they sell well all over the world.

Our products include all kinds of offset machines, cutting machines, binding machines, bill printing machines, digital stencil duplicator machines, digital print machines, spray printing machines, print finishing machines and other kinds of printing, packing, advertisement and office equipment.

*Primary products:

Automatic High Speed Flute Laminater

ZXSCM Book Case Making Machine

650UV Coating Machine

ZX-650C Manual Paper Pasting Machine

Box Making Machine

Hot Melt Gluing Machine and Gluing Machine

Table Gluing Machine

Paper Pressing Machine.etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!