GFM1500-A High Speed Flute Laminator Machine for packing 20KW 160m/min

Product Description:

Function:

The paper can be laminated with paperboard to increase the strength and thickness of the material or special effects. After the die-cutting, it can be used for packaging boxes, billboards and other purposes.

Principles:

The top paper is sent out by the upper paper feeder and sent to the start detector of the positioning mechanism for detection. Then the bottom paper is sent out; after the bottom paper is coated with glue on the glue wheel, the top paper and the bottom paper are respectively conveyed to the paper Synchronous detectors on both sides, after the detection, the controller calculates the error value of the paper and the bottom paper, and the servo compensation device on both sides of the paper compensates the paper to a predetermined position for splicing, and then pressurizes the conveying. The machine presses the paper and conveys it to the delivery machine to collect the finished product.

Parameters

| Model |

GFM1500-A |

GFM1700-A |

GFM1900-A |

GFM2200-A |

| Max size |

1500*1500mm |

1700*700mm |

1900*1900mm |

2200*2100mm |

| Min size |

380*380mm |

360*400mm |

500*500mm |

500*500mm |

| Top paper |

150-800gsm |

150-800gsm |

150-800gsm |

150-800gsm |

| Bottom paper |

300gsm-10mm |

300gsm-10mm |

300gsm-10mm |

300gsm-10mm |

| 160meters/min |

160meters/min |

160meters/min |

160meters/min |

| Max speed |

12000pcs/hour |

12000pcs/hour |

12000pcs/hour |

12000pcs/hour |

| Power |

20kw |

20kw |

22kw |

22kw |

| Accuracy |

±1mm |

±1mm |

±1mm |

±1mm

|

Applicable materials:

Top paper --- 120 ~ 800g/m paper

Bottom paper--- ≤10mm ABCDEF corrugated board ≥300gsm

Glue - Corn starch glue, white glue etc., PH value between 6 ~ 8

Structural features:

Adopting the world's leading transmission control system, only need to input paper size system auto-tuning.

Computerized high-speed fitting, up to 150m/min.

High speed feeder, with four sets of forward nozzles and four sets of suction nozzles.

Feed Block adopts low stack cardboard, which can fit the paper to the pallet, and can install track-assisted pre-stacker

Use multiple sets of electric eyes to know the advance position of the bottom line, and make the servo motor on both sides of the face paper to independently rotate to compensate the upper and lower paper alignment, which is accurate and smooth.

Full-function electronic control system, using human-machine interface and PLC program model display, can automatically detect operating conditions and work records.

Automatic glue replenishment system can automatically compensate for lost glue and cooperate with glue recycling.

FEATURES

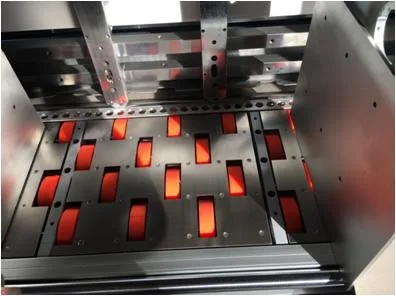

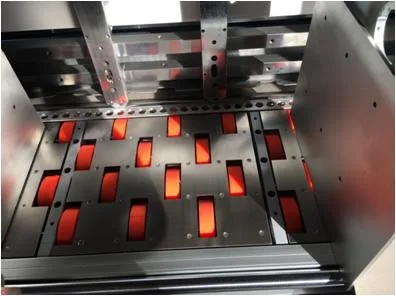

1.BOTTOM SHEET FEEDING

Use imported Servo motor controlling system, with Japan NITTA suction belt and big air blower to ensure smooth feeding of 2ply, 3ply, 4ply, 5ply and cardboard.

2.TOP SHEET FEEDING MECHANISM

Both paper lifting and feeding nozzle of high speed auto dedicated feeder can be freely adjusted to be adapted to both thin and thick paper. Together with Becker pump, ensure top feeding paper run fast and smoothly.

3.ELECTRICAL SYSTEM

Designed and adopt U.S.A Parker motion controller together with Yaskawa Servo system and inverter, Siemens PLC to ensure machine run at max. speed and accuracy as premium performance and running stability.

4.PRE-STACK PART

Pre-pile system with preset function can be set as paper size through touch screen and oriented automatically to reduce set-up time efficiently.

5.Transmission System

Gates synchronical belt together with SKF bearing as main transmission is adopted to ensure stability. Both pressure rollers, dampening roller and glue value can be easily adjusted by handle with mechanical encoder.

6. POSITIONING SYSTEM & GLUE ROLLER

Photocell together with Parker Dynamic module and Yaskawa Servo system ensure the accuracy of orientation of top and bottom paper. Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min. glue quantity.

7.GLUE ROLLER:

Stainless steel roller,never rust, after narrowly grinding, guaranteed the minimum amountglue coated evenly. Down roller be cleaned by water roller.

8.LEADING EDGE FEEDING SYSTEM(OPTION)

This system is for option,more suitable for large size and thick bottom sheets.

OPTIONS:

1.LEADING EDGE FEEDING SYSTEM

Lead edge ensure thick corrugated board like 5 or 7 layers run smoothly even under very curing condition.

2.SHAFTLESS SERVO FEEDER

Shaftless servo feeder is utilized for extra long sheet at flexible motion.

Machine transport and packing

FAQ

Q1: Are you a manufacturer?

Yes, we are specialized manufacturer of hot foil stamping machine and die cutting machine in China over 20 years.

Q2: Do you have stock products to sell?

We manufacture machines in batch. So most of machines have in stock, please check with us before ordering.

Q3: How about installation and training?

Installation and training: If purchaser's engineer travels at own cost to China, free training session. If engineer sent to purchaser's factory, all travel cost paid by purchaser.

Q4: How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator's error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product's photos and videos to make every detail clear.

Why choose us?

_____________________________________________________________________

1.Our brand "INNOVO" is well-known in our domestic market and over 70 countries and territories. Europe, South America, Latin America, Southeast Asia, Middle East, Africa etc.

2.Genuine products with excellent quality. Company has always proved the 100% quality.

3.After-sales service and technical assistance: company provides after sales service and technical assistance as per customers' requirement and needs. After-sales service provided engineers available to service machinery overseas.

4.Cost saving: lon-life, shock resistant and high reliability bearings with excellent quality and better performance, resulting in increased cost saving.

5.Less cost of purchase: We are the manufacturer directly.

6.Attendant customers queries promptly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!