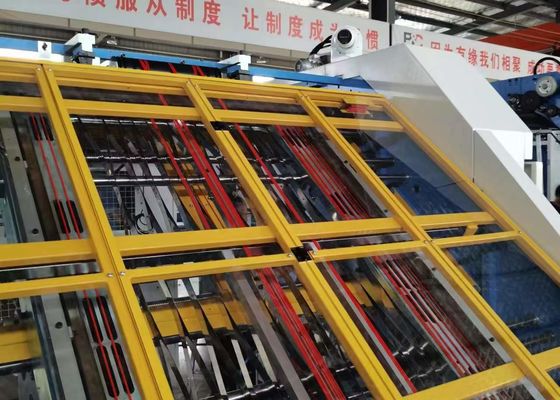

High Speed Corrugated Laminating Machine FLute Laminator

Product Description:

INTRODUCTION:

The servo laminating machine is the newest member of the laminating family. This machine combines the motion control system and servo correction device, there are multiple sets of photoelectric sensor induce the position of the bottom sheets, and in the mean time the servo motors on both sides of the top sheet make independent compensation action, so the top sheet and the bottom sheet can be positioned accurately. Servo laminating machine is easy to operate, we only need to type in the paper size and the machine would adjust the feeder, the bottom paper feeding and the pressure unit automatically, which realized the intelligent operation.

Remarks: The top sheet could be the printed color sheet, filmed paper and UV varnished and paper from offset printing machine.

Principles:

The top paper is sent out by the upper paper feeder and sent to the start detector of the positioning mechanism for detection. Then the bottom paper is sent out; after the bottom paper is coated with glue on the glue wheel, the top paper and the bottom paper are respectively conveyed to the paper Synchronous detectors on both sides, after the detection, the controller calculates the error value of the paper and the bottom paper, and the servo compensation device on both sides of the paper compensates the paper to a predetermined position for splicing, and then pressurizes the conveying. The machine presses the paper and conveys it to the delivery machine to collect the finished product.

Adopting the world's leading transmission control system, only need to input paper size system auto-tuning.

Computerized high-speed fitting, up to 150m/min.

High speed feeder, with four sets of forward nozzles and four sets of suction nozzles.

● The multifunctional rack of the bottom paper are suitable for curved corrugated.

● Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min glue quantity.

● Use a circulating glue system to reduce glue loss and stabilize glue adhesion effect.

● One -click adjustment of the whole machine (just enter the paper size).

● Automatic paper collection and manual paper collection can be converted at any time.

● Video monitoring (optional).

Parameters:

| Model |

ZGFM 1500 |

ZGFM 1700 |

| Max size |

1500*1500mm |

1700*1700mm |

| Min size |

360*380mm |

360*400mm |

| Top Paper |

120-800g |

120-800g |

| Bottom paper |

≤10mm ABCDEF corrugated board ≥300gsm cardboard |

≤10mm ABCDEF corrugated board ≥300gsm cardboard |

| Max speed |

150m/min |

150m/min |

| Power |

25kw |

27kw |

| Stick accuracy |

±1mm |

±1mm |

BRANCH INTRODUCTION:

1. BOTTOM SHEET FEEDING

Use imported Servo motor controlling system, with Japan NITTA suction belt and big air blower to ensure smooth feeding of 2ply, 3ply, 4ply, 5ply and cardboard.

2. TOP SHEET FEEDING MECHANISM

Both paper lifting and feeding nozzle of high speed auto dedicated feeder can be freely adjusted to be adapted to both thin and thick paper. Together with Becker pump, ensure top feeding paper run fast and smoothly.

3. ELECTRICAL SYSTEM

Designed and adopt U.S.A Parker motion controller together with Yaskawa Servo system and inverter, Siemens PLC to ensure machine run at max. speed and accuracy as premium performance and running stability.

4. POSITIONING SYSTEM & GLUE ROLLER

Photocell together with Parker Dynamic module and Yaskawa Servo system ensure the accuracy of orientation of top and bottom paper. Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min. glue quantity.

5. Transmission System

Gates synchronous belt together with SKF bearing as main transmission is adopted to ensure stability. Both pressure rollers, dampening roller and glue value can be easily adjusted by handle with mechanical encoder.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!